Why we invested in Sunrise Robotics

by Carina NamihEurope’s manufacturing base is vast - larger than the US, second only to China, and responsible for 15% of the continent’s GDP. But it’s also at a demographic tipping point. Roughly a third of its 32 million-strong workforce is set to retire within 15 years. And automation - the obvious answer - hasn’t delivered for the majority.

Today’s automation is falling short. The industrial robots in use today were designed for a world of predictable, high-volume production. They’re expensive, inflexible and take months to install. They make sense for the biggest car factories - but not for the messy, fast-changing reality of high-mix, low-volume manufacturing, which makes up 65% of Europe’s production base.

Why Sunrise is Different

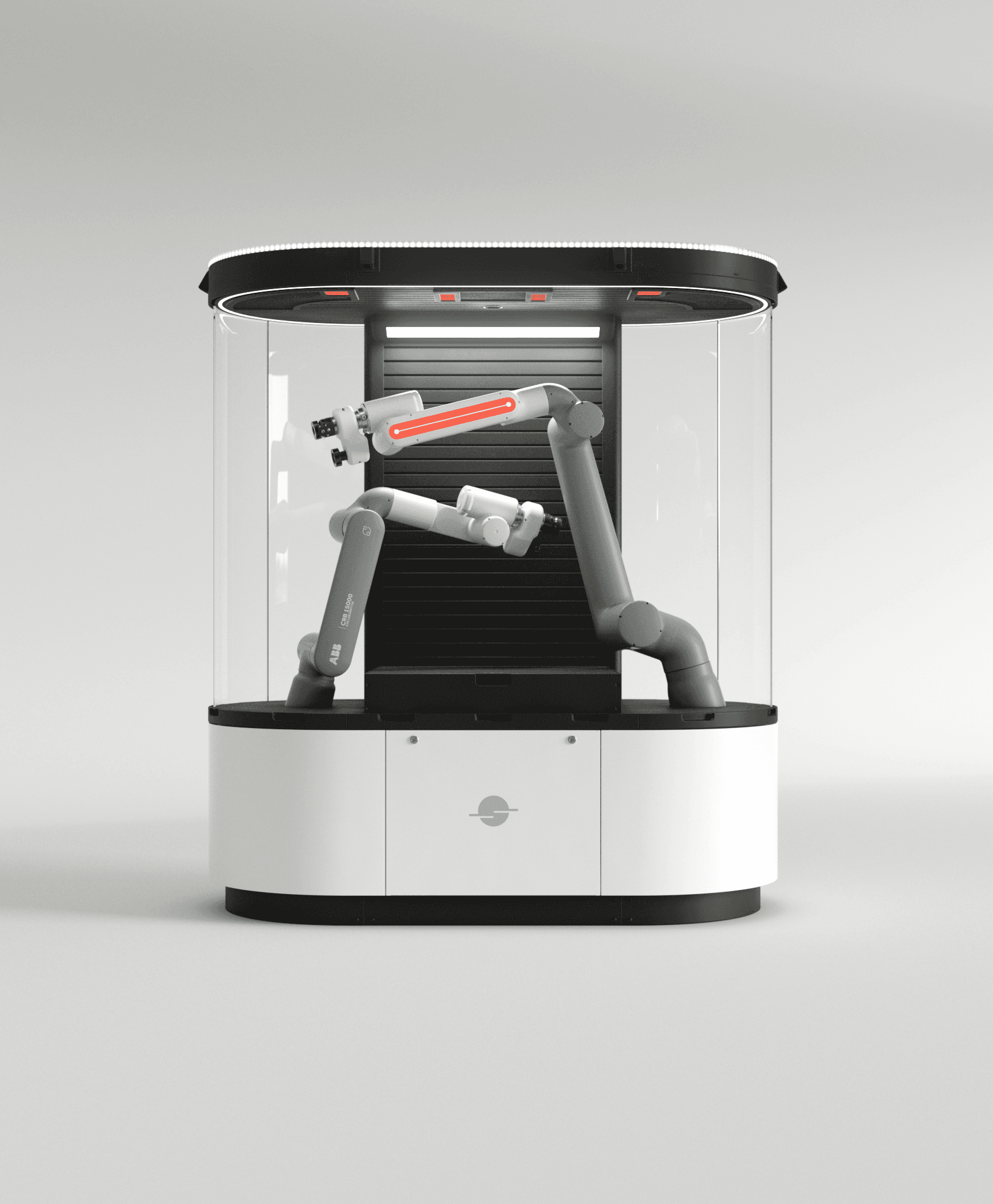

Sunrise Robotics is building intelligent robotic cells that can be deployed in hours, not months, and trained in simulation rather than programmed by hand. They’re productising robotics the way SaaS productised enterprise software: standardised, scalable, fast to deploy and smart enough to adapt to new tasks without rework.

They record a video of a factory workstation and a human doing the task. Sunrise creates a digital replica, trains the robot in a fleet-scale simulation environment and ships a ready-to-go cell. By the time the physical cell is wheeled onto the factory floor, it’s already done thousands of hours of task training. First deployment to full productivity? Just four hours.

These aren’t science projects - they’re production-ready systems. Each cell has twin arms, a 360º visual field, local edge compute and embedded safety protocols. They’re designed to slot into existing human workstations and take on tasks that are hard to hire for and painful to retain around. And once trained, a cell’s knowledge becomes fleet-wide knowledge - shared across Sunrise deployments via simulation and continuous data collection. This turns each new install into a force multiplier for the entire network. This is real-time, industrial collective intelligence.

A Founding Team Built for this

CEO Tomaz Stolfa previously founded and scaled Layer and Vox.io. CCO Joe Perrott ran production for over 100 million devices at PCH for customers like Amazon and Apple. And CTO Marko Thaler has been building autonomous systems since the late ’90s. After scaling his drone startup to acquisition, he took on the CTO role at the acquiring manufacturer, where he led the production of millions of components a year.

Together, they have the rare combination of deep experience in robotics, AI, and manufacturing. As experienced founders, they had the discipline and the humility to learn from the customer first - they spent months touring hundreds of factories across Europe before writing a single line of code.

Investing from Experience

My own experience in manufacturing - and the frustrations I witnessed in deploying robotic systems at HelixNano - made the Sunrise vision click immediately. At Helix, we explored every automation tool on the market. What we found was that the real bottleneck wasn’t hardware, but deployment. Systems were brittle, painfully slow to install, and broke down the moment the production line changed.

Sunrise fixes that, not just with better code, but with a fundamentally different product architecture. It’s closer to a self-driving car than a traditional robot - modular, sensor-rich, trained in simulation, and capable of learning on the job. Their end-to-end stack integrates perception, motion planning, safety, and control in a way that’s both deeply engineered and obsessively practical.

Early Traction and Clear Demand

In just 18 months from first engineering hire, Sunrise has deployed its first robotic cell into production at a customer facility. The feedback has been glowing. Each of these early customers is seeing real productivity gains and reducing their reliance on hard-to-hire labour in the most volatile parts of their production lines. One customer told us that Sunrise was the first automation solution they’d seen that actually fit their needs - not a lab demo, but a factory tool. Sunrise already has 10+ design partners, from PCB assembly to high-performance battery manufacturing, and the team expects 10–15 units deployed by the end of the year. Their pipeline is full, and their biggest constraint isn’t demand - it’s making sure they scale with precision.

Why Now?

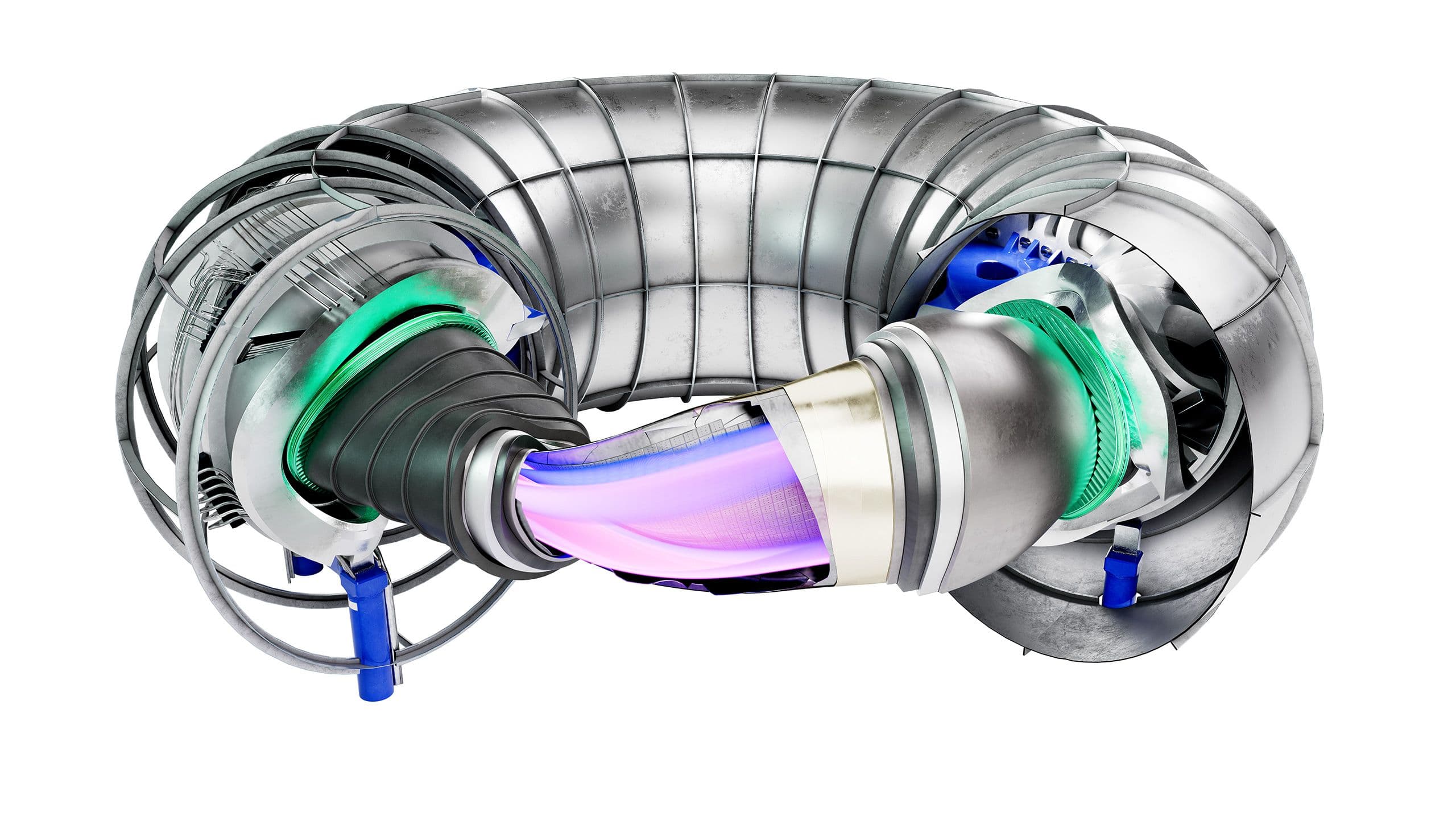

The building blocks have only recently aligned. Robotic arms are cheaper and more capable. Cameras and sensors are higher quality and lower cost. Edge compute is powerful enough to run complex models in real-time, without needing a data centre in the loop. And AI training methods - particularly in sim-to-real transfer - have reached an inflection point where they can be productised, not just published. Sunrise sits at the confluence of these trends. It’s turned what was once a years-long integration exercise into a 10-week cycle from demo to deployment. And it’s only getting started.

Industrial Strength for a New Era

Sunrise is not just a robotics company. It’s a force multiplier for humanity. A belief that we can solve our most urgent demographic and economic challenges not by replacing people, but by augmenting them - freeing humans from tedious, low-retention tasks, and letting them focus where their creativity and experience matter most. And now, more than ever, we need companies like Sunrise - building sovereignty through capability - as Europe stands up on its own, determined to shape its industrial future.